Magnetic Levitation Intelligent Production Lifting System

With the development of oil and gas fields, deep well, high inclination well and horizontal well are widely used. The application of traditional lifting equipment such as pumping unit and rodless pump technology, is seriously redistricted by lifting height, off-wear and other problems.

A complete set of solutions is given: Magnetic Levitation Pulse Intelligent Production Lifting system(MLIP lifting system). The technology realizes the lifting without pumping unit and rod, meeting the requirements of deep pumping, anti-off-wear, energy saving, safety and environmental protection. The mechanical transmission part is optimized in design. The whole system has high power factor and less power loss.

This system can be applied in deep wells, horizontal wells, high inclination wells and oil Wells. It can also be used in conventional wells, tight oil and gas wells, shale oil and gas Wells, coal-bed methane wells and other oil and drainage gas production fields.

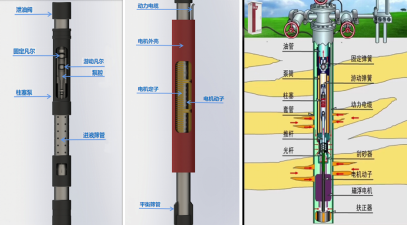

MLIP lifting system consists of three parts: control cabinet, magnetic levitation power system including motor, two-way motion reciprocating pump.

1.Product principle and function introduction

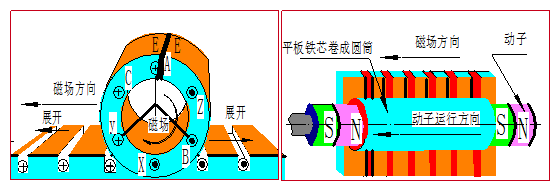

This product is the most important civil application of electromagnetic levitation and electromagnetic ejection principle. The magnetic levitation technology and design are applied in power part. The unit consists of two parts: the rotor made of relatively precious and rare earth elements magnetically retained permanent magnets and the stator composed of coil electromagnet. The compound alternating magnetic field force generated by the current on the stator tube produces fully controlled components, respectively:

The ring-shaped central magnetic term makes the magnetic levitation rotor levitate.

The forward ejection linear force term makes the whole system have the upward lifting force.

2.Product workflow

After the power supply is transformed to the rated voltage of the unit through the transformer, it reaches the maglev motor through the junction box and submersible cable; the up and down reciprocating motion of the mover of the maglev motor drives the bidirectional reciprocating pump.

When the pump column moves upward, the fixed valve ball is opened by the thrust of the oil to pump the liquid.

When going down, the valve ball is quickly seated along the guide valve, and the pump chamber begins to be filled with liquid.

Work in cycles and achieve the lifting production.

Downhole pressure sensor, through the power cable transmission signal to achieve intelligent automation.

3.The key flexible control technology

The specific flexible control technology of encoderless maglev motor can save energy greatly

At the same time, timely control and change the current direction in order to stabilize the magnetic field direction at the millisecond level.

Precise realization of the actuator's magnetic ejection and flexible magnetic field protection after the actuator's ejection

It can ensure the stability of the whole magnetic levitation system

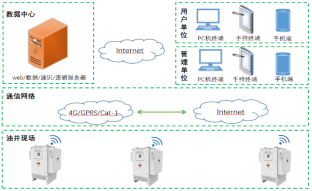

4.Remote communication platform

Through 4G/GPRS/CAT-1 network real-time collection system operating status, the collected data is stored in the cloud data center

User units and management units use PC terminals, handheld terminals and mobile phones to access the data center through the Internet

5.Relying on the "intelligent cloud platform", intelligent, digital and visual oilfield construction can be realized.

Magnetic levitation pulse submersible electric pump unit adopts rodless oil production technology, which is different from the traditional pumping unit "machine-rod-pump" system, and can realize the online adjustment of the control system without stopping.

The system can collect downhole pressure, temperature, star voltage, leakage current and other operating data in real time, and remote transmission to the centralized control cente

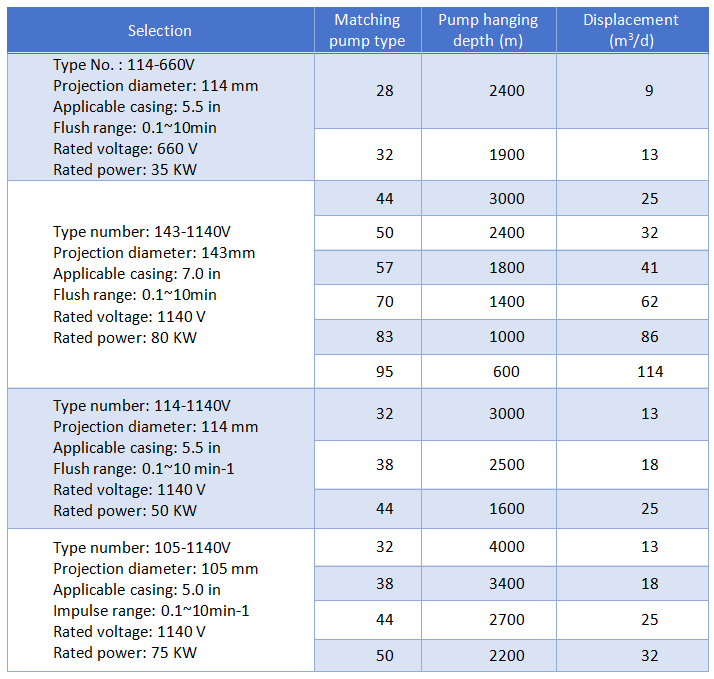

6.Product technology platform and selection