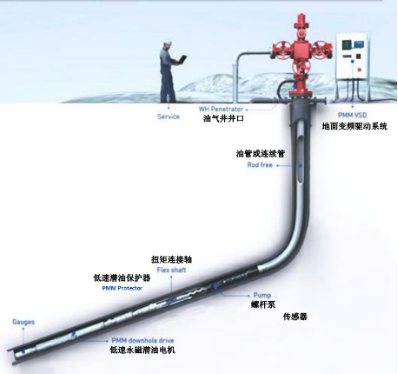

Permanent Magnet Submersible Electric Pump System

Permanent magnet motor electric subm

ersible pump (PMMESP) adopts the third generation of permanent magnet technology. On the basis of the current conventional electric submersible pump system, the underground drive motor is upgraded from ordinary induction motor to permanent magnet motor. It is a rodless oil production system with smaller volume, more efficient and energy-saving, stable and reliable, and has a wider application range and better application benefits than the conventional electric submersible pump system.

The product breaks through the technical bottleneck that foreign manufacturers must provide downhole units and ground equipment (otherwise incompatible); The technical performance parameters of the motor exceed some manufacturers (such as Schlumberger, Baker Hughes). The motor is compatible with the interface size of the conventional electric pump manufacturers in the industry, and has excellent versatility, which foreign manufacturers can not do; Break through the control technology of permanent magnet submersible motor, compatible with V/F and vector control, ground control equipment compatibility is excellent, foreign manufacturers can not do; The advantage of cost performance is obvious.

Product advantages:

Quadrupole permanent magnet motor, nominal 3000RPM@100Hz

Temperature rating 204°C

Third generation rare earth permanent magnet - NdFeb

Independent research and development of patented technology

Energy saving 20% ~ 30% or more

Full torque start, overload multiple 1.5

Single section motor power is high, no series connection, stable and reliable to achieve high power requirements

Operation range 0-150HZ (4500RPM), displacement and head range coverage is wider

Small size specification, strong adaptability to dogleg degree

Torque ripple is small, the vibration of the whole machine is small

The interface size of the unit is common in the industry, compatible with the ground frequency conversion equipment of the conventional submersible pump.

In addition to conventional well conditions, but also more suitable for high gas-liquid ratio, heavy oil, low production fluid, below the perforation section of the motor heat dissipation of the application environment.

350 Series small diameter unit - Maximum outside diameter 3.5 "(89mm, the smallest in China), can be used for minimum 4-1/2" casing/liner combined production or 7" casing split production.

The motor size is short, which can realize the connection between the factory protector and the motor, and the factory pre-filling oil, saving the field operation time.

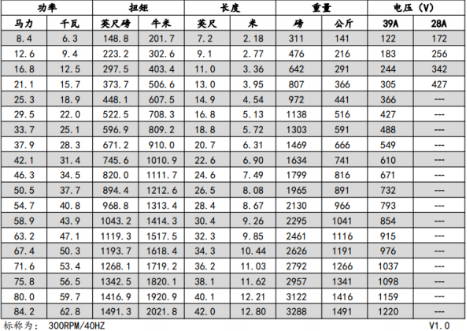

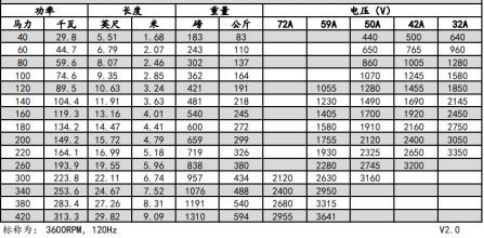

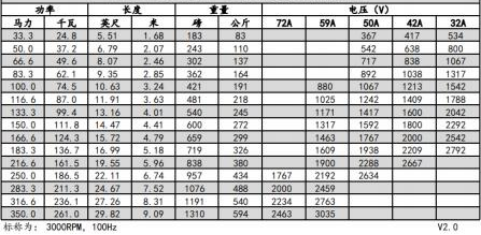

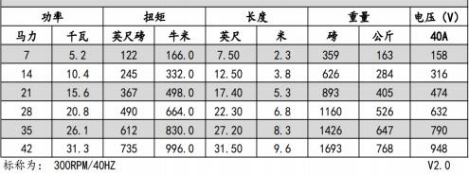

Submersible permanent magnet 350 series (89mm) constant speed motor

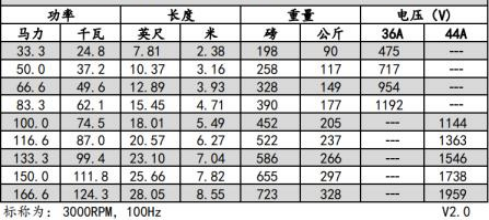

Oil submersible permanent magnet 450 series (114mm) constant speed motor

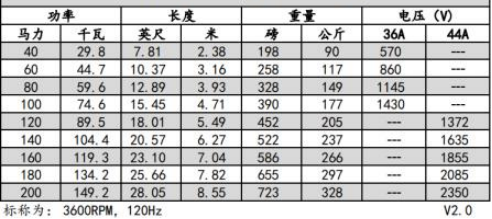

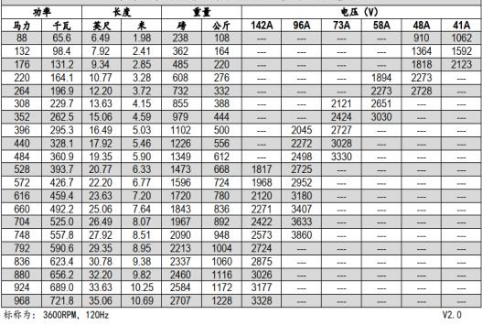

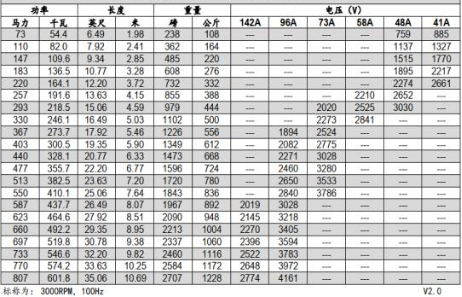

Submersible permanent magnet 562 series (143mm) constant speed motor

Direct oil submersible permanent magnet motor 450 (114mm) low speed direct drive motor

Direct drive oil submersible permanent magnet motor 562 (143mm) low speed direct drive motor