Instant Solid Acid

1)Introduction

The instant solid acid is a multi-element organic acid, which can be dissolved at room temperature to form a high-strength acid liquid, has little corrosion to ground pipelines, and has a fast dissolution rate. It can be prepared and used on site, eliminating the need for special equipment for acid liquid transportation and storage, which greatly saves Time and economic costs. For high temperature formations, when used with supporting corrosion inhibitors, it can greatly reduce the corrosion of casing and cables. It has the characteristics of high acid concentration, low corrosion rate, convenient preparation and high dissolution efficiency.

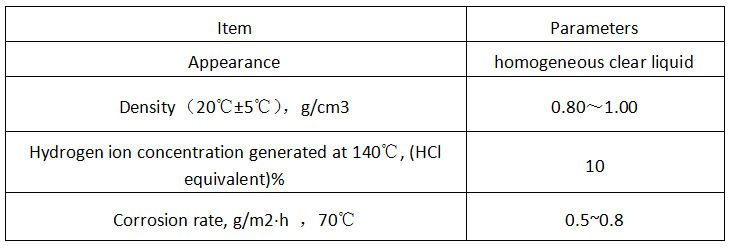

2)Technical parameters

3) Advantages

Status is solid, easy to transport.

Easily soluble in water, soluble in cold water

Equivalent to 15% hydrochloric acid at a ratio of 1:10 with water, high efficiency.

Low cost of use and simple operation. Eliminates transportation and storage costs.

4) Product Appearance

Sustained-Release Solid Acid

1) Introduction

The slow-dissolving solid acid is a special polymer type acid with a particle size between 400 mesh and 6 mm, which can be customized according to requirements. The product has a melting point over 180°C, does not agglomerate in hot water, has good dispersibility and heat resistance, and is suitable for pumping. The requirements for pumping equipment are also low, and it is not corrosive in water at room temperature.

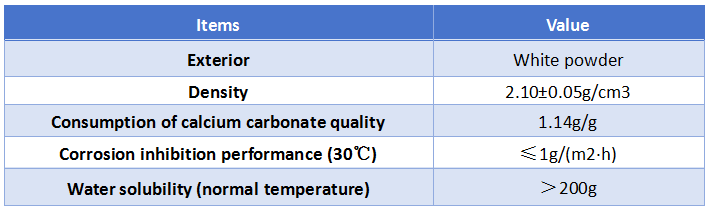

2) Technical parameters

3)What it replaces

Hydrochloric acid (inconvenient to transport or Environmental restrictions)

Gelling acid/ cross-linked acid(High price and complicated process)

4) Advantages

Congestion of organic and inorganic clogs, slowing down of speed, no secondary sedimentation, deep decongestion

Solid acid delayed the reaction speed of acid rock, expand the scope of acid erosion, improve the effect of acid erosion production.

100% environmentally friendly polycondensation of solid acid, high temperature hydrolysis of the formation of organic acids can be biodegradable to carbon dioxide and water.

5) Product Appearance

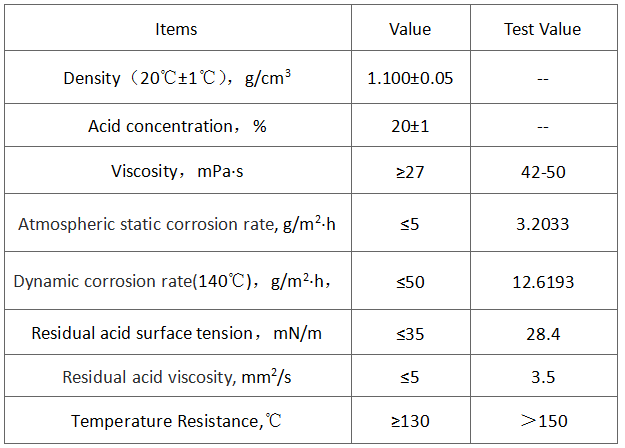

Diverting Acid

For the acidization of heterogeneous reservoirs, acid liquid is more likely to enter the high permeability zone for dissolution, which results in further enhancement of the heterogeneity of the reservoir.

Principle: During the acid-rock reaction, the viscosity of acid fluid is increasing while the filtration is reducing, which blocks the high permeability zones; Fresh acid with low viscosity is more likely to enter into low permeable zones, which achieves a uniform acid distribution to transform the low permeability zones.

Acid Formula:20%HCl+5.0% diverting acid +2.5~3% corrosion inhibitor +1.0~1.5%corrosion inhibitor synergist + 1.0% iron ion stabilizer;

Backflush breaking fluid formula: 10% mutual solvent + 1.0% clay stabilizer + 1.0% drainage aid.

Gelled Acid

Due to fast acid-rock reaction speed and large acid fluid loss in conventional acidization, the effective length of acid fractures is short and does not meet the requirements of deep acidization.

The gelled acid system has high viscosity and low filter loss, which can reduce the diffusion rate of H+ to the rock surface, thereby slowing down the acid-rock reaction rate, increasing the effective length of acid fractures and achieving the purpose of deep acidization.

Gelled acid system formula: 20% HCl+2.5~3% gelling agent+1% iron ion stabilizer+2.5~3% corrosion inhibitor+1.0~1.5% corrosion inhibitor synergist+1.0% drainage aid+1.0 % clay stabilizer.

Typical Properties

Authigenic Acid

In the acid fracturing of ultra-deep and high-temperature carbonate reservoirs in oil and gas fields, the commonly used gelled acid-rock reaction is too fast and acidizing conductivity at the far end of fractures is very low. The acidizing can not achieve deep penetration. Authigenic acid gradually generates higher concentration hydrochloric acid under high temperature. This characteristic can slow down the acid rock reaction rate, improve the conductivity of the middle and far ends of the fracture, and maximize the effective fracture length; after pumping the authigenic acid, the use of ordinary gelling acid acidization can improve the near-well conductivity and achieve the purpose of improving the overall fracture conductivity and deep penetration stimulation.

At present, a third-generation autogenic acid system has been developed. This system reacts with carbonyl compounds and metal salts, hydrolyzes at formation temperature to produce hydrochloric acid and releases hydrogen ions at fixed points in the depth of the fracture to achieve deep acidizing at far end of fractures. It is harmless and environmentally friendly.

Authigenic acid formula: 0.5~0.8% thickener + 10% high temperature authigenic acid for acidization + 1~2% drainage acid + 1% clay stabilizer + 0.6% fracturing acidization cross-linking agent + 0.1% polymer gel breaker agent.

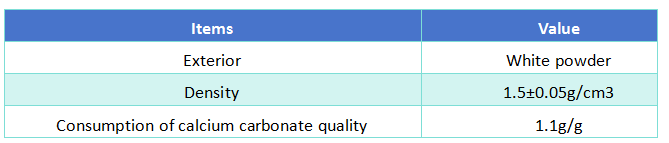

Property