Dispersant

1) Introduction

This product is a kind of functional copolymer, which is the core treatment agent of ultra-high density drilling fluid. Meet the requirements of 2.5g/cm3-2.8g/cm3 high density drilling fluid. The drilling fluid dispersant can improve the rheological properties of high-density drilling fluids, can withstand temperatures above 180°C, and has good compatibility with drilling fluid loss control agents and other additives.

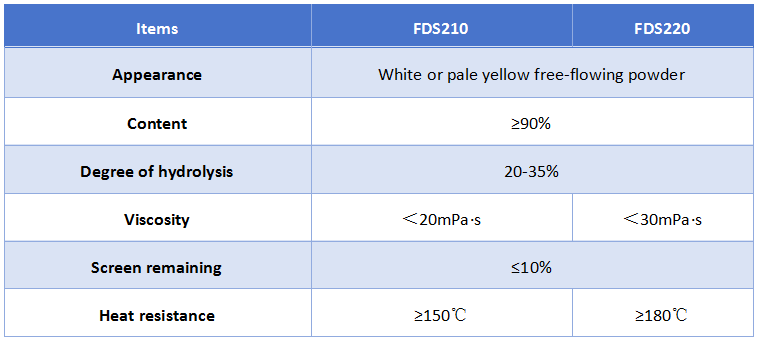

2) Technical parameters

Coating Agent

1) Introduction

This product is a kind of polyacrylamide copolymer, which can better maintain the stability of drilling fluid performance, and can effectively inhibit shale hydration expansion and keep drill cuttings from dispersing, which is easy to remove. This series of polymers has a good coating effect on cuttings in fresh water, salt water and saturated salt water, and the temperature resistance is above 150℃.

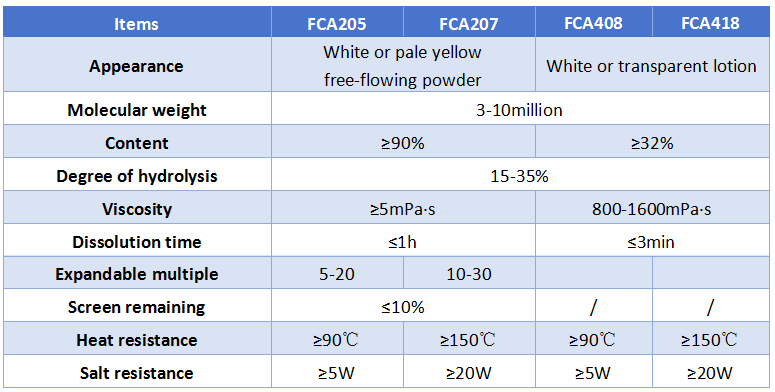

2) Technical parameters

Solidified Formation Water

1)Introduction

This product is a type of polyacrylamide copolymer. During the overhaul operation, solidified formation water can avoid harmful pollution such as water sensitivity, salt sensitivity, alkali sensitivity, wetting reversal, surface adsorption, water lock, blockage, and permeability decrease caused by the pollution of the workover fluid.

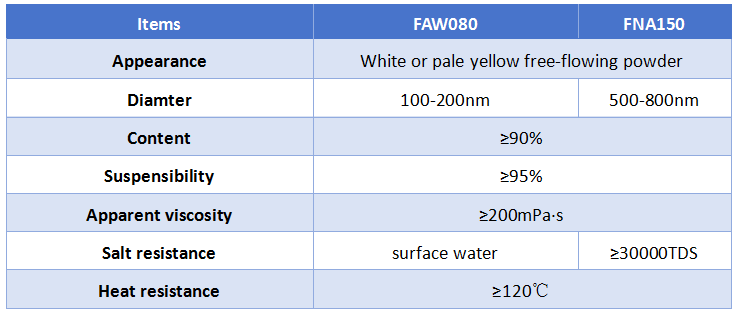

2)Technical parameters

3)What it replaces

Common plugging agent is not resistant up to 150℃.

4) Advantages

Withstand huge differences in formation pressure and temperature,

Has a temporary plugging effect.

Good dispersion and suspension properties, ensure the rheology and sand-carrying properties of the workover fluid.

Emulsifier

TRAPERMUL-P is the primary emulsifier in TAPER conventional oil-based drilling fluid systems. It is designed for use in shale gas and tight oil blocks and is suitable for use in both diesel and mineral oils.

The TRAPERMUL-S coemulsion is used in conjunction with the TRAPERMUL-P main emulsion for optimal thermal stability and filtration reduction, specifically for shale gas and tight oil blocks.

The CONMUL-P emulsifier is the main emulsifier in CON's new generation of high performance oil-based drilling fluid system. The synergic effect of the CONMUL-S co-emulsifier can provide a good water-in-oil emulsion, effectively control the high temperature and high pressure filtration loss, and ensure the thermal stability of the system.

The NEOMUL-S emulsifier is the co-emulsifier of the new generation of high performance oil-based drilling fluid system, and also plays the role of wetting agent. The synergic effect with CONMUL-P main emulsifier can provide a good water-in-oil emulsification state, wet solid particles, and effectively control high temperature and high pressure filtration.

EXERMUL is the only emulsifier in EXPER's high-performance high-temperature drilling fluid system. Used alone, it provides excellent water-in-oil emulsification, effective oil hydration, controlled fluid loss, and overall stability of the system.

The main component of TRAPERMU-P is an organic fatty acid mixture that provides stable water-in-oil emulsification, improves thermal stability, and reduces the amount of high-pressure and high-temperature fluid loss.

Wetting Agent

TRAPERWET is a high-quality oil wetting product used in TRAPER's traditional oil-based drilling fluid operations, most commonly to increase and treat water intrusion, but also to reduce the overall system's viscosity cut, primarily in shale or tight gas drilling.

CONWET wetting agent is a high quality oil wetting product used in CON oil-based drilling fluids, most commonly used to aggravate and treat water intrusion, but also used to reduce the overall system viscosity. In particular, it is used in water-based drilling fluids to wet the clay solid phase of gas hydrate or combustible ice formations, delaying the diffusion and decomposition of gas hydrate or combustible ice.

EXPERWET wetting Agent, an oil wetting product used in EXPER's UHT oil-based drilling fluid system, also acts as an auxiliary emulsifier and works best with EXPERMUL. EXPERWET also improves the thermal stability of the system, controls HP/HT filtration and resists contamination in the temperature range of 40°C to 260°C.

Water-based Lubricants

FRILEX is an amino based lubricant for water-based drilling fluids that reduces torque and resistance by reducing the coefficient of friction, preventing sticking. The direct effect of reduced torque and drag is increased ROP for use in water-based drilling fluids, production water and saltwater drilling fluids, especially in extended-reach and horizontal Wells. FRILEX is an economical, high-performance lubricant for use in high pH, high salt, high calcium and silicate systems. It is inherently biodegradable and non-fluorescent.

FRILEX-PRO is a high-performance lubricant that can be fully dispersed in water. It can reduce torque and resist sticking by reducing the coefficient of friction, preventing sticking. It is suitable for all types of water-based drilling fluid systems, and its unique wetting properties reduce the possibility of mud coating. FRILEX-PRO is produced from vegetable oils and fatty acids, which are free of aromatics and pose no harm to humans or the environment.

Water-based Inhibitors

AMPOHIB shale inhibitor is a small molecular weight amphoteric polymer product used to inhibit active clay and sensitive shale in water-based drilling fluids. It is suitable for fresh water, seawater and high salinity water-based systems with temperature resistance of up to 200℃. The main effect of AMPOHIB is to reduce the dilution rate, frictional resistance, excited suction pressure and the risk of mud inclusion in the mud system through strong inhibition. Ampohib is suitable for low solid content, soilless phase or low solid system containing pre-hydrated bentonite.