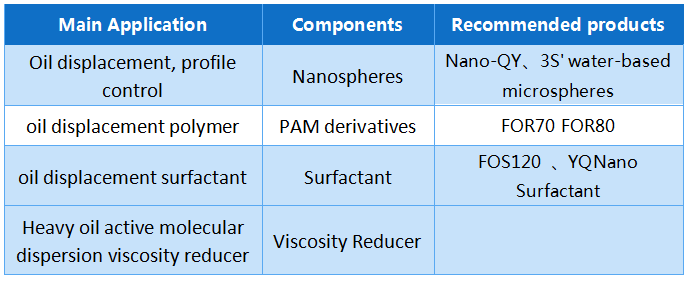

EOR Additives

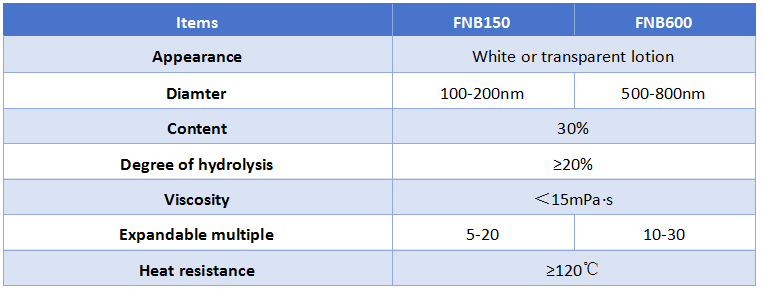

Nanospheres

1) Introduction

Nanospheres are composites composed of nanometer or micrometer sized polymer particles. It can be widely used in deep control and flooding in oilfields.

The microspheres have the characteristics of high temperature resistance, strong salt resistance, and oil field produced liquid sewage resistance. The particle size of the microspheres can reach the nanometer scale, which can easily enter the micropores of low-permeability reservoirs, and play a role in deep profile control and oil displacement. At the same time, the microspheres have the characteristics of delayed expansion and can enter deeper parts of the formation.

2) Technical parameters

3) How to use

Nanospheres can be used for deep control and flooding in low-permeability oilfields. Microspheres can be dispersed rapidly in water. The added amount of microspheres is 0.1-0.5%.

4) Advantages

Innovative particle system specially developed for deep profile control

Very small cross-linked polymer particles penetrate deeply into the formation

Overcomes the injectability (drag coefficient < 2) and cost (2-3% pore volume of the leakage layer) of traditional polymer solutions

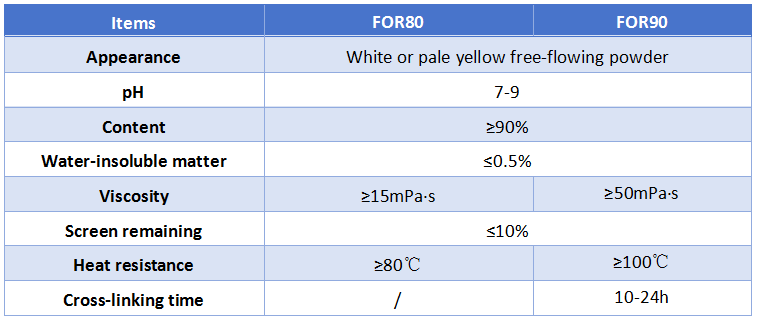

Polymer for EOR

1) Introduction

This product is a kind of polyacrylamide multi-component copolymer, which can be used in binary or ternary composite flooding in tertiary oil recovery in oil fields to improve the oil-water mobility ratio. It can also be used in deep profile control to improve oil recovery.

This product is temperature resistant and salt resistant.

2)Technical parameters

3) What it replaces

Ordinary polymers are used in large quantities and are expensive.

4) Advantages

Good salt resistance

High viscosity in low concentration

Surfactant for Oil Displacement

1) Introduction

The surfactant is composed of biological surfactant, Gemini surfactant and anionic surfactant in a certain proportion. The product has the ability to form ultra-low interfacial tension with crude oil, while also having the ability to disperse, emulsify and strip crude oil.

The surfactant has the characteristics of high surface activity, good water solubility, small dosage, temperature and salt resistance, etc. It can be widely used in oil field single well huff and puff, heavy oil cold recovery and surfactant-polymer composite flooding technology.

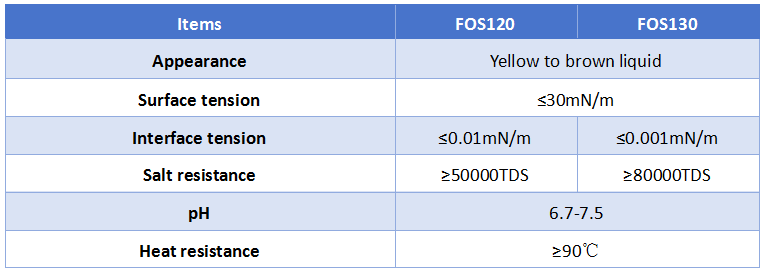

2) Technical parameters

3) What it replaces

Ordinary surfactants are effective in high concentration.

4) Advantages

Good water solubility in small dosage

Low surface and interface tension

Good salt resistance

Good heat resistance

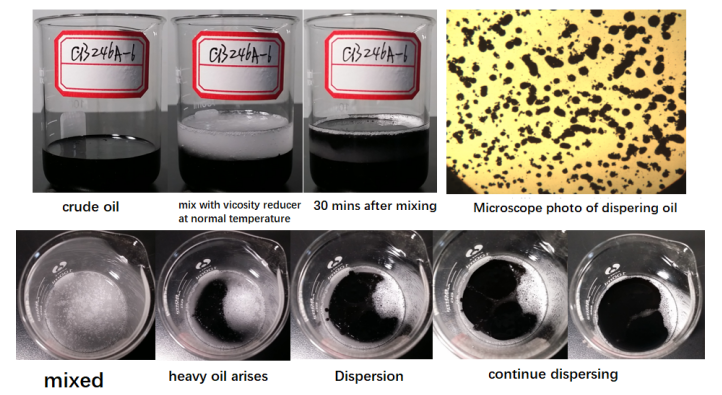

Heavy Oil Active Molecular Viscosity Reducer

1) Introduction

Active molecular viscosity reducers can spontaneously disperse heavy oil. The viscosity reduction mechanism includes homologous intercalation, polar deconstruction, active dispersion and peeling migration. This viscosity reducing agent is aimed at heavy oil with a viscosity of <50000mPa·s under formation temperature, with a static viscosity reduction rate of >95%. It is mainly used on site to increase production through stimulation of single wells and viscosity reducing agent flooding in well groups; effective viscosity reducing temperature: 20~220ºC; Salt tolerance 150000mg/L, Ca2+ concentration tolerance 50000mg/L.

2) Advantages

Low cost → no need to move the pipe string, saving cost of measures;

Convenient operation → sewage liquid preparation and oil jacket annulus injection;

Low formation damage → Complete flowback and less formation retention;

Stable production → Production declines slowly during the well lifecycle, remaining the same as or exceeding the previous round of steam stimulation.